Types of Dryer Venting Materials

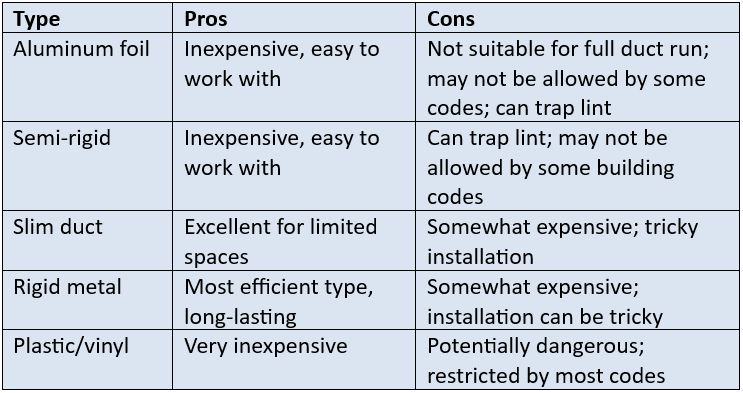

Dryer venting is the mechanism that allows clothes dryers to exhaust humid air to the outdoors as they dry your clothes. Dryer vent or duct tubing comes in a variety of materials, and below we outline the five major types, along with their pros and cons.

(1) Aluminum Foil Duct

Aluminum foil ducting is made from flexible aluminum foil and has an embedded spiral wire for reinforcement. It is normally used to connect the dryer to the main (rigid) duct that runs to the outdoor outlet and should not be used for an entire duct run.

Aluminum foil duct is inexpensive and easy to work with, but its ribbed walls can trap lint, leading to a possible fire hazard and therefore should be used in short segments that remain accessible for regular cleaning.

(2) Semi-Rigid Duct

Semi-rigid aluminum duct tubing is flexible and similar to foil tubing but much more rigid. Like foil, this should be used only for the transition from dryer to main duct, and it should not be hidden in walls or floors.

Semi-rigid metal duct is relatively inexpensive and can be used for the entire duct run (dryer outlet to exhaust vent hood) only if the duct run is short (less than 8 feet), only if it is exposed (not hidden), and only if local code allows it.

(3) Slim Duct

Slim duct is a telescoping rigid aluminum tubing used in tight spaces. It has a wide rectangular shape except for the two ends where it connects to the dryer and the vent outlet, which are round. Using slim duct allows you to push the dryer very close to the wall and can be a great space-saver. Most slim ducts can be adjusted from about 27 inches to about 48 inches in length and can be installed vertical, horizontal, and diagonal.

Slim duct is more expensive than aluminum and semi-rigid, but is a good option when wall clearance is an issue.

(4) Rigid Metal Duct

Rigid metal duct is the only allowable material for installations that are hidden inside walls and floors. It has a very smooth interior surface, so air flows through with little friction, and catches the smallest amount of lint of any duct material.

Rigid metal duct is extremely durable and efficient, and therefore is more expensive than the other types of ducting. Additionally, building codes often allow for runs as long as 35 feet*, making it a good choice for larger installations.

*Note: the number of elbows and fittings used in the line will shorten the overall allowable run length.

*Note: There may be some dryers on the market that specify a duct length of less than 35 feet (10 668 mm), and the manufacturer’s instructions would prevail in such case.

(5) Flexible Plastic or Vinyl Duct

The flexible plastic or vinyl duct is similar to aluminum foil duct but has a thin plastic wall rather than metal foil. This type of duct has a high potential to collect lint, overheat, and cause fires – and so has fallen out of use and is now restricted for use by many municipalities. If your dryer duct is made of this material, you should replace it with a safer type of duct.

UP NEXT MONTH:

PART 2: The Importance of Dryer Vent Maintenance